3M™ Novec™ Availability

- 3M™ Novec™ 7100 – In Stock

- 3M™ Novec™ 7200 – In Stock

- 3M™ Novec™ 7300 – In Stock

- 3M™ Novec™ 7500 – In Stock

- 3M™ Fluorinert™ FC-40 – In Stock

- 3M™ Fluorinert™ FC-72 – In Stock

- 3M™ Novec™ 72DE – In Stock

- 3M™ Novec™ 73DE – In Stock

- 3M™ Novec™ 72DA – In Stock

- 3M™ Novec™ 649*** – In Stock

- 3M™ Novec™ 612*** – In Stock

- 3M™ Novec™ 1230*** – In Stock

***Direct molecule replacement in stock.

Availability varies on other fluids. Contact us for more information and Novec™ pricing.

3M™ Novec™ Production Ending – Final Order Deadline

March 31, 2025 is the last day that orders for 3M™ Novec™ products will be accepted due to the phaseout.

Take control of your future by switching to BestSolv™ Engineered Fluids today. Don’t wait and risk production delays!

3M™ Novec™ for Solvent Cleaning and Vapor Degreasing

Best Technology is a U.S. nationwide authorized 3M™ Novec™ distributor of 3M™ Novec™ Engineered Fluids. 3M™ places a significant amount of trust in Best Technology’s extensive experience in precision cleaning chemistries and applications.

3M™ Novec™ Engineered Fluids are non-flammable, non-ozone depleting, low-toxicity solvents and cleaners with low global-warming potential. The 3M™ Novec™ family of precision cleaning solvents offers an ideal balance of:

- high employee safety exposure limits

- low environmental impact

- excellent cleaning performance.

The ever-changing EPA, regulatory, employee and environmental demands require industrial cleaning solvents that are not only safe for the employee, but also for the environment. The phaseouts of Ozone Depleting Substances like AK-225 / HCFC-225, nPB / n-propyl bromide, TCE, HFC and also past solvents included in the Montreal Protocol have brought on an industry calling for next-generation replacement solvents that are safer for employee and environment yet still provide the level of precision cleaning seen by previous-generation solvents.

The 3M™ Novec™ line of precision cleaning fluids represents a new generation of precision cleaning solvents for vapor degreasing that are among the most successful replacement solvents offered in the market today.

3M™ Novec™ solvents are typically a drop-in replacement in most vapor degreasers, resulting in easily-implemented safety and regulatory compliance without the purchase or modification of capital manufacturing equipment. Since Novec™ industrial cleaning solvents are non-flammable, they can be used safely in a wide variety of applications.

3M™ Novec™ Engineered Fluids Materials Compatibility

Will 3M™ Novec™ Engineered Fluids work with my application? This is the key question for engineers looking to change from one type of solvent cleaning to another. Use the table below to pinpoint which Novec™ fluid is ideal for your application. Our applications engineers are also available to discuss unique materials compatibility requirements.

Materials Compatibility for 3M™ Novec™ Engineered Fluids

| Cleaning Performance | 3M™ Novec™ Engineered Fluids | ||||||||

| Light Duty | Medium Duty | Heavy Duty | |||||||

| 7100 | 7200 | 71IPA | 71DE | 71DA | 72DE | 72DA | 73DE | ||

| Replacement for | CFCs | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| HCFCs | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| HFCs | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| TCE | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| nPB | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Aqueous | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Co-Solvent Cleaning | ✔ | ✔ | ✔ | ||||||

| Effectively Removes Soils | Light Oils | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Medium Oils | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Fluoro Lubes | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Particulates | ✔ | ✔ | ✔ | ||||||

| Ionic Soils | ✔ | ✔ | ✔ | ||||||

| Greases | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Fluoro Greases | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Silicones | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| Fluoro Silicones | ✔ | ✔ | ✔ | ✔ | |||||

| Flux | ✔ | ✔ | ✔ | ||||||

| Wax | ✔ | ✔ | ✔ | ✔ | |||||

| Solubility | Fluorocarbon | High | High | High | Medium | Medium | Low | Low | Low |

| Hydrocarbon | Medium | Medium | Medium | High | High | High | High | High | |

| Silicone | Low | Low | Medium | Medium | Medium | High | High | High | |

| Compability with Materials | Plastics | High | High | High | Requires Customer Testing | Requires Customer Testing | Requires Customer Testing | Requires Customer Testing | Requires Customer Testing |

| Acrylics | High | High | High | None | None | None | None | None | |

| ABS / Polycarbonate | High | High | High | None | None | None | None | None | |

| Solvent-Resistant Plastics (nylon, PTFE, epoxy, PEEK) | High | High | High | High | High | High | High | High | |

| Silicones | Medium | Medium | Medium | Low | Low | Low | Low | Low | |

| Ceramics | High | High | High | High | High | High | High | High | |

| Metals | High | High | High | High | High | High | High | High | |

| Precision Cleaning Application | Vapor Degreasing | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Immersion | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Hand-Wipe | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Spray Cleaning | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

Materials Compatibility Testing to Industry Standards

3M™ Novec™ Engineered Fluids are compatible with a wide range of substrates used in aerospace materials, medical devices, electronics and other parts requiring very clean, spot-free finishes. Independent laboratory compatibility test results of 3M™ Novec™ fluids are listed below.

| Test Description | ASTM # | Novec™ 7100 |

Novec™ 71DE |

Novec™ 7200 |

Novec™ 72DA |

Novec™ 72DE |

Novec™ 73DE |

| Sandwich Corrosion Test | F1110 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Acrylic Stress Crazing | F484 | Conforms | Doesn’t conform* |

Conforms | Doesn’t conform* |

Doesn’t conform* |

Doesn’t conform* |

| Paint Softening Test | F502 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Hydrogen Embrittlement | F519-77 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Hydrogen Embrittlement | F519,1C | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Residue Test | F485 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Immersion Corrosion Test | F483 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Cadmium Removal Test | F483 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Low Embrittling Cadmium Plate | F111 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

| Flash Point | D56 | Conforms | Conforms | Conforms | Conforms | Conforms | Conforms |

* Novec™ fluids 71DE, 72DA, 72DE, and 73DE caused visible stress crazing of the acrylic plastics. Testing performed by Scientific Materials, Inc.

Source: 3M

Benefits of 3M™ Novec™ Engineered Fluids in Precision Cleaning and Vapor Degreasing

Safer and environmentally friendly

The primary benefit of using Novec™ fluids is that they are safer and more environmentally friendly than the solvents that they replaced. With significant environmental, safety and toxicity concerns on the use of the vapor degreasing solvents n-propyl bromide (nPB) and trichloroethylene (TCE), and a global phase-out of ozone-depleting substances like hydrochlorofluorocarbons (HCFCs), many engineers are seeking a safer, more sustainable alternative. Novec™ fluids are an excellent drop-in replacement because they are engineered for:

- High margin of safety for workers

- Zero ozone depletion potential (ODP)

- Low global warming potential (GWP)

- Excellent cleaning performance

Unlike many other cleaning and vapor degreasing solvents, Novec™ fluids are environmentally sustainable and are not scheduled for regulatory phase-out. Under the EPA’s Significant New Alternatives Policy (SNAP), they are acceptable substitutes in metals, electronics and precision cleaning applications. Both Novec™ 7100 and Novec™ 7200 are approved by the EPA’s SNAP program for “use without restriction.” Unlike many solvents, Novec™ fluids are not hazardous air pollutants (HAPs). Neat Novec™ fluids are also exempt from the EPA’s definitions for Volatile Organic Compounds (VOCs).

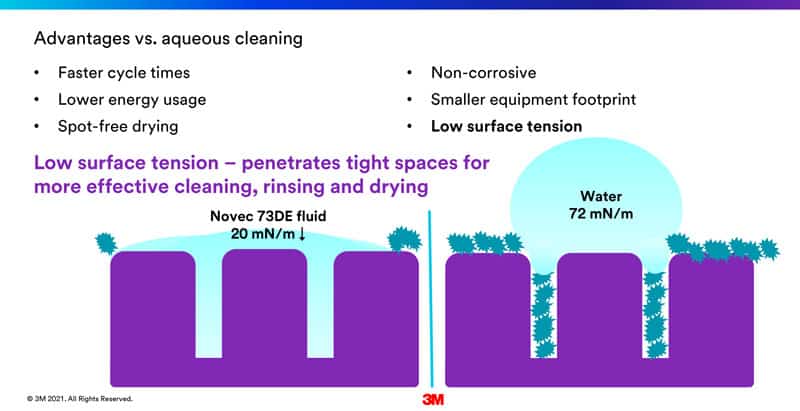

More effective cleaning

Because of their low surface tension, 3M™ Novec™ Engineered Fluids can penetrate tight spaces and aspect ratios on complex parts. After thoroughly cleaning hard-to-reach areas, the fluids then drain off easily so they don’t become trapped in small spaces. They evaporate and dry off quickly with very low NVR (non-volatile residue), unlike aqueous systems that leave residue or water spotting. The result is that parts get clean faster and costly complications associated with “drag-out” solvent losses are reduced. Vapor degreasing with Novec fluids offers:

- Improved cleaning of parts with complex geometries

- Faster dry times for improved cycle times

- Better solvency for organic soils

- Freedom from chemistry that supports biological growth

- Spot-free results with less chance of corrosion

Efficient use of resources

Use of Novec™ fluids with a vapor degreaser is less equipment- and energy-intensive compared to that of aqueous systems. Because a solvent system recycles the solvent through distillation, most of the solvent is reused. Other advantages of solvent cleaning with Novec™ Fluids vs. aqueous systems include:

- Easier to use with cellular manufacturing

- Significantly lower electricity costs

- Conservation of water

- Smaller equipment “footprint”

- No drying equipment needed

- Lower long-term cost of ownership

For more information, see our article Why Use a Parts Cleaning Solvent?

Cleaning Applications with 3M™ Novec™ Engineered Fluids

| Example Parts | Compatible Substrates | Soils Removed |

| Artificial Hearts Heart Valves O-Rings Contact Lenses Eyeglass Lenses Catheters Needle Caps Endoscope Parts Gel Capsules Needles Stents Wires Cables Capillary Tubes Orthopedic Implants Dental Implants Spinal Implants Mobile device parts Disk drive components |

Polycarbonate Silicone Rubber “Hard” Plastics Acrylic Stainless Steel Titanium Nickel/Cobalt Aluminum Ceramics Circuit Boards |

Oils Particulate Mold Releases Mounting wax Skin oils Buffing compound |

Source: 3M

Note that not all Novec™ fluids are appropriate for cleaning parts containing certain plastics and elastomeric materials. See product information or contact us for details on materials compatibility.

Top-Selling 3M™ Novec™ Engineered Fluids for Precision Cleaning and Vapor Degreasing

- 3M™ Novec™ 71IPA Engineered Fluid

Based on Novec 7100 HFE and isopropyl alcohol, this fluid is ideal for light cleaning and degreasing tasks. HFE-71IPA is metals and plastics compatible. A true azeotrope, HFE-71IPA has essentially constant vapor and liquid composition at its boiling point. - 3M™ Novec™ 72DA Engineered Fluid

Based on a blend of azeotropes designed for medium to heavy-duty precision cleaning of metallic parts and solder flux residue. The high solvency and low toxicity make it an ideal replacement for ozone-depleting compounds (HCFC225 / AK 225), hydrofluorocarbons (HFC Dupont Vertrel), chlorinated solvents, and n-propyl bromide (nPb). A true azeotrope, HFE-72DA has essentially constant vapor and liquid composition at its boiling point. - 3M™ Novec™ 73DE Engineered Fluid

Based on a blend of azeotropes designed for heavy-duty precision cleaning of metallic parts, dewaxing, and solder flux residue. A perfect alternative replacement to nPB and TCE.

Precision Cleaning Specs for 3M™ Novec™ Engineered Fluids

| Cleaning Performance | Formulation | Boiling Point °C |

Vapor Pressure kPa |

Surface Tension mN/m |

| Light Duty | ||||

| Novec™ 7100 | Novec™ 7100 (100%) | 61 | 26.9 | 13.6 |

| Novec™ 7200 | Novec™ 7200 (100%) | 76 | 16.0 | 13.6 |

| Novec™ 71IPA | Novec™ 7100 (95%) Isopropanol (5%) |

55 | 27.6 | 14.5 |

| Medium Duty | ||||

| Novec™ 71DE | Novec™ 7100 (50%) t-DCEa (50%) |

41 | 51.0 | 16.6 |

| Novec™ 71DA | Novec™ 7100 (53%) t-DCEa (45%) Ethanol (2%) |

40 | 50.8 | 16.4 |

| Heavy Duty | ||||

| Novec™ 72DE | t-DCEa (70%) Novec™ 7200 (20%) Novec™ 7100 (10%) |

44 | 46.7 | 19 |

| Novec™ 72DA | t-DCEa (68%) Novec™ 7200 (20%) Novec™ 7100 (10%) Isopropanol (2%) |

44 | 48.0 | 18 |

| Novec™ 73DE | t-DCEa (85%) Novec™ 7300 (15%) |

48 | 35.1 | 19.9 |

a trans-1,2-dichloroethylene

Source: 3M

With its azeotropic properties, each of the 3M™ Novec™ Cleaner blends has essentially constant vapor and liquid composition at its boiling point. This allows for extremely stable characteristics for cleaning various oils and soils. Novec™ cleaners are widely accepted fluids by our customers especially in the medical device and aerospace industry.

The 3M™ Novec™ fluids can also be combined with various solvating agents for co-solvent and bi-solvent processes depending on the application.

3M™ Novec™ Aerosols

3M™ Novec™ is also available in aerosol cans from Best Technology, sold as 6-packs of aerosol containers.

| Product | Container Sizes Available |

3M™ Data Sheets |

| 3M™ Novec™ Contact Cleaner Plus |

6-pack of 11 oz. cans | Data Sheet |

| 3M™ Novec™ Contact Cleaner |

6-pack of 11 oz. cans | Data Sheet |

| 3M™ Novec™ Contact Cleaner/Lubricant |

6-pack of 12 oz. cans | Data Sheet |

| 3M™ Novec™ Electronic Degreaser |

6-pack of 12 oz. cans | Data Sheet |

| 3M™ Novec™ Flux Remover |

6-pack of 12 oz. cans | Data Sheet |

3M™ Novec™ Voluntary Phase Out Announcement

On December 20, 2022, 3M™ announced plans to exit per- and polyfluoroalkyl substance (PFAS) manufacturing and work to discontinue the use of the PFAS in its product portfolio by the end of 2025.

As an authorized 3M™ Engineered Fluids distributor, Best Technology remains committed to our customers throughout this transition and continues to receive 3M™ Novec™ products. We will continue to advocate for our customers to fulfill current orders as well as secure products for future orders. We highly recommend preparing for the phaseout by testing BestSolv™ replacement fluids.

Order Now

For Best Technology’s stocking information and data sheets, please see the 3M™ Novec™ Engineered Fluids for Solvent Cleaning stock chart.

3M™ Novec™ Price and Ordering

For purposes of product stewardship, 3M™ Novec™ fluids cannot be sold directly online and are available for customers in the United States only.

Please contact our chemical sales department for a quote by clicking the “Get a Quote” button, or call 612-392-2414, ext. 2.