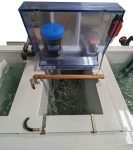

Titanium anodizing equipment delivers an improved surface finish for titanium parts. Depending on the type of anodizing performed, a titanium anodize system can provide a wear coat (Type 2) or add color to titanium parts (Type 3). Best Technology offers titanium anodizing lines for both types of titanium anodizing, backed by our decades of experience […]

Surface Finishing Equipment - Articles

Hex Chrome Phase Out and Alternatives for Conversion Coating

What is Hexavalent Chromium? Often referred to as hex chrome, hexavalent chromium is a form of the metallic element chromium, commonly used in manufacturing. Chromium is especially useful for its corrosion resistance, hardness and durability. Other names for hex chrome include chromium(VI), chrome VI, chromium 6, chromium(6+) and Cr VI. Hexavalent chromium compounds contain the […]

Alodine Chem Film Tank Line

Application The Best Technology chromate conversion coating system allows for flexible manufacturing of many chem film and Alodine® needs. System can also be designed and built for both MIL-DTL-5541 Type 1 hexavalent chromium and Type 2 hexavalent chrome free processes. System tank configuration is dictated by Type 1 or 2 classification. MIL-DTL-5541 Type 2 hexavalent chrome free equipment […]

What is Alodine / Chem film / Chromate Conversion Coating?

Chromate Conversion Coatings for Aluminum (Chem Film) per MIL-DTL-5541 What is Alodine®? Also known as chem film or chemfilm, Alodine® is a chromate conversion coating that protects aluminum and other metals from corrosion. Related products include Iridite®, TCP-HF, Bonderite®, and Chromicoat®. The process of applying a chromate conversion coating (chem film) is referred to as […]

Surface Finishing Equipment and Systems

Best Technology is the industry’s leading supplier of surface finishing equipment and finishing machines. System types include: chem film / Alodine systems, mass finishing equipment / parts tumblers, titanium anodize lines, and 3D printed surface finishing and support removal systems. Click on images below to learn more about each type of surface finishing machine. Chromate Conversion […]

Vibratory Bowl Mass Finishing Systems

Vibratory Bowl Finishers operate by placing a mixture of your parts together with polishing media in a bowl-shaped machine that uses vibration to agitate the parts and media. At the end of the cycle, the parts travel up a ramp to discharge the parts and recapture the polishing media for the next batch of parts. Vibratory […]

What is Titanium Anodizing? How to Anodize Titanium

What is Titanium Anodizing? Titanium anodizing is an electrolytic finishing process that manipulates the oxide layer on the surface of titanium via electric current. The titanium item forms the anode (positive electrode) of an electrolytic cell; hence the name “anodize.” Anodizing has a long history in the aerospace industry, where it was first used in […]

Centrifugal Barrel Finishing Machines for Deburring and Polishing

What is a Centrifugal Barrel Finishing Machine? Centrifugal barrel finishing machines are the fastest and most cost-effective method for deburring or polishing large quantities of metal parts at once. Also known as an industrial parts tumbler, rotary tumbler, metal parts tumbler or harperizer, a centrifugal barrel tumbling machine grinds metal surfaces using a cyclical sliding […]

Mass Finishing Machines

INDUSTRIES SERVED: Medical Device Aerospace Electronics Disc Drive Automotive Semiconductor Best Technology represents the industry’s leading mass finishing machines for industrial parts finishing. These machines include centrifugal barrel parts tumblers, vibratory tub systems, vibratory bowl systems, and centrifugal disc systems. These finishing machines for metal parts have applications across many industries. Best Technology also offers […]