Automated Parts Washer System Description

The fully-automated A-MKT parts washer uses a conveyor and walking beam system to move and index baskets of parts through agitated immersion cleaning, rinsing and drying processes. This automatic parts washer is especially effective at heavy-duty ultrasonic cleaning of metal parts to remove fine particulate, buffing and polishing compounds, and water-soluble cutting fluids and coolants used during CNC machining.

Automated industrial cleaning consoles empower the operator to simply load or unload a basket of parts and return to other tasks. This automated parts washer offers flexibility to tune each station according to the size and mass of parts. This allows for highly effective cleaning of a wide variety of sizes and weights of metal parts.

Automatic Parts Washer System with Conveyor

From left to right, the automatic parts washer system features stations for Load, Wash, Rinse, Dry, and Unload.

From left to right, the automatic parts washer system features stations for Load, Wash, Rinse, Dry, and Unload.

Video: Fully Automated Indexing Agitated Immersion Wash, Rinse, Dry Parts Washer

Automated Parts Washer System Features

This automated parts washer system includes a roller-conveyor at the loading and unloading stations. This allows the operator to load (or unload) a basket of parts and return to other tasks. When the washer is ready for parts, it will automatically index the basket from the load station to the wash station, from the wash station to the rinse station, from the rinse station to the dryer, and from the dryer to the unload station.

Roller Conveyors View from Load Station

Sensors at the load station ensure that the basket is placed correctly on the in-feed side of the machine, and sensors on the unload station automatically stop the machine from indexing when the unload station is completely full of baskets. This means the operator is freed up during the wash/rinse/dry cycle to attend to other tasks, knowing that the parts baskets will not collide.

Agitated Immersion Washing Station

A platform lift is included in both the wash and rinse tanks that allows the parts baskets to be agitated in the solution inside the tank. Controls are included for both long and short strokes, as well as slow or fast agitation. This agitation moves the solution constantly around and through the parts to ensure thorough cleaning and rinsing of each part. Additionally, high-flow pumps with in-tank reduction nozzles add turbulation as the platform moves up and down.

Oil Removal System – Surface Sparger

The automated parts washer system includes an oil removal system to remove true oils from the part surfaces. This oil removal system includes a surface sparger to push all floating oils into a side mounted tank dam.

Oil Removal System – Tank Dam

The oil removal system dam sends surface oils to an external decant belt skimmer tank.

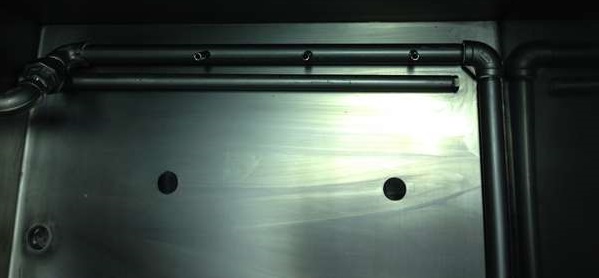

Automatic Parts Washer System Rear View – PLC / Electrical Control Panel

Digital temperature controls and cycle timers are available for each of the wash, rinse and dry stations. This allows the user to set each tank/station individually.

Automated Drying Station – Heated Air Knives

The dryer station of the automatic parts washer includes both heat and blowers to ensure rapid and complete drying of all parts.

Video: Fully Automated Indexing Conveyor Parts Washer with Passivation

Common Applications

The superior part exterior and part internals flushing action makes agitated immersion automatic parts washers excellent for:

- Removal of oil and chips from machined components, castings and housings

- Removal of buffing and lapping compounds

- Cleaning prior to welding, deburring, brazing, blasting or other post-process applications where surface cleanliness is critical

- Precision cleaning prior to assembly or final packaging

- Rapid proto-typing of wide variety of sizes of metal parts

Related Parts Washing Systems

- Agitated Immersion Parts Washers – Our industrial parts washers with agitated immersion can be automated using similar features.

- Agitated Immersion Ultrasonic Parts Washer – Our precision cleaning agitated immersion parts cleaning systems are automated using this walking beam automation.

- Agitated Immersion Multi-Tank Passivation Systems – Automating agitated immersion systems allows for operator-free parts cleaning prior to nitric or citric acid passivation.

Start Your Automated Parts Washing Project Now

Ready to start your automatic parts washing project? Contact a parts washing expert at Best Technology today to discuss your project and receive a free proposal.