Chromate Conversion Coatings for Aluminum (Chem Film) per MIL-DTL-5541

What is Alodine®? Also known as chem film or chemfilm, Alodine® is a chromate conversion coating that protects aluminum and other metals from corrosion. Related products include Iridite®, TCP-HF, Bonderite®, and Chromicoat®. The process of applying a chromate conversion coating (chem film) is referred to as chromating.

A chromate conversion coating (chem film) is a type of chemical conversion coating. In chemical conversion coatings, the metal undergoes a chemical reaction at the surface. Unlike plating, which adds a new layer to the metal surface, a chemical conversion coating transforms the existing metal surface into a protective layer via chemical reaction.

The primary benefit of an Alodine coating (chem film) is aluminum corrosion protection. But chemical film coating with Alodine offers other benefits. The chemical film or Alodine coating leaves a base that provides better adhesion for organic coatings, and it can protect against the loss of electrical conductivity.

What is Chem Film? Video Overview

Chromate conversion coatings (chem film) are used for heat sinks, automotive wheels, and everyday aluminum hardware and components. In aerospace applications, chromate conversion coatings are used on aircraft hulls, including shock absorbers, side and torsion struts, landing gear, and flight control systems such as rudder systems and wing parts.

Chem film is applied by dipping, brushing or spraying, and the chromate conversion coating thickness does not change the dimensions of the part. The layer of transformed metal is very thin: The thickness of Alodine coating for aluminum is typically only 0.00001-0.00004 inches (0.25-1 μm). Aluminum conversion coating improves the adhesion of both paint and primer if it is applied to an aluminum surface prior to the primer.

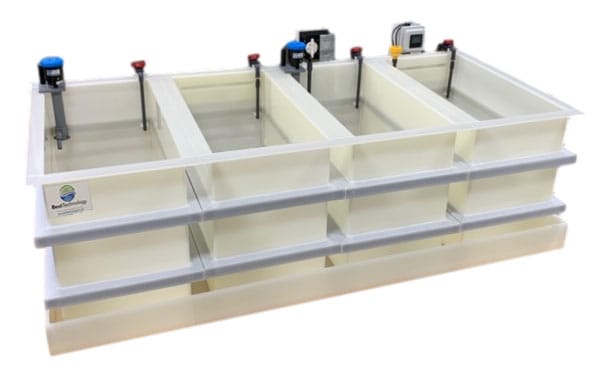

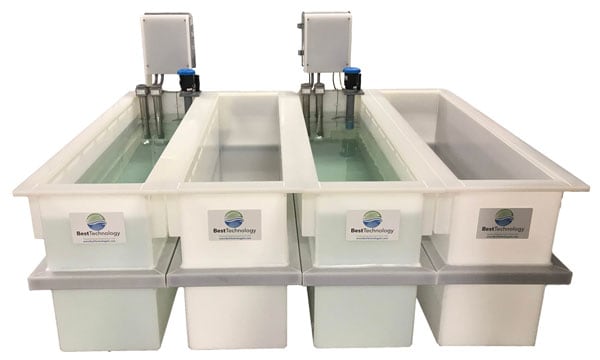

Alodine Equipment for Applying Chromate Conversion Coatings

Types of Chromate Conversion Coating (Chem Film)

The MIL-DTL-5541 specification, Chemical Conversion Coatings on Aluminum and Aluminum Alloys, is the most commonly used specification for chromating aluminum. The MIL-DTL-5541 specification distinguishes between different types and classes of conversion coating for aluminum. The Type of a chem film coating depends on the chemical composition of the coating material, while the Class relates to its intended purpose.

For Types, the MIL-DTL-5541 standard defines two types of chemical conversion coating for aluminum, based on the presence or absence of hexavalent chromium in the coating.

MIL-DTL-5541 Type 1

MIL-DTL-5541 Type 1 contains hexavalent chromium, also known as hex chrome. This was the customary process for many years, and was used until safer chemicals were introduced.

Exposure to hexavalent chromium is now tightly regulated in the United States by both the EPA, as an environmentally hazardous chemical, and by OSHA, as a carcinogenic chemical. If using Type 1 for MIL-DTL-5541 spec work, be sure to check with your state or county for processing permits that pertain to proper venting and disposal of hex chrome. The need for additional ventilation can add significantly to the cost of a Type 1 chem film system.

MIL-DTL-5541 Type 2

MIL-DTL-5541 Type 2 is known as hex-free chromating. In this type the hexavalent chromium has been replaced with trivalent chromium, titanium or zirconium, and it is typically accepted as the standard across many industries. Best Technology partners with Chemeon, an industry leader in hex-free trivalent chromium coating chemistries, to offer a hex-free product named TCP-HF (hexavalent free) that has approvals for many aerospace and military applications.

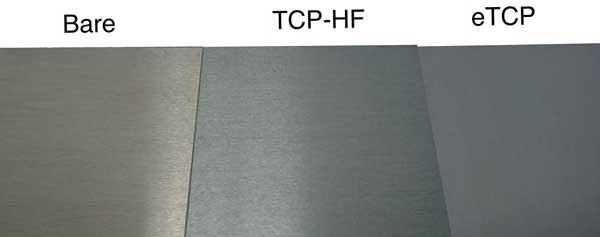

The hex-free coating can result in a faint blue color appearing almost unchanged from bare material. eTCP is a colored version of TCP-HF developed to exhibit visual identification for quality control purposes.

Advancements in trivalent chromate coating on aluminum allow the trivalent process to have many benefits over Type 1:

- Faster to apply

- Room temperature to apply. This saves on electrical energy that would otherwise be needed to heat the tanks. Lack of heated tanks also eliminates concerns about evaporative losses.

- Fewer process steps (typically 5 steps vs. 9 steps for hexavalent chromium, Type 1)

Classes of Chromate Conversion Coating (Chem Film)

The Class of a chemical film coating depends on its intended purpose. The MIL-DTL-5541 spec describes two classes that are commonly used in chemical film applications.

MIL-DTL-5541 Class 1A

Class 1A: This class of chromate coating on aluminum tends to be much thicker than other classes, as well as darker, which provides a high grade of corrosion protection for unpainted items. It also improves adhesion of paint finish systems on aluminum and aluminum alloys. The military uses chemical agent-resistant coating (CARC) paint on a wide variety of vehicles and equipment as added protection against chemical agents.

MIL-DTL-5541 Class 3

Class 3: This class of chromate coating on aluminum has two objectives: It is designed not only to protect against corrosion, but also to reduce interference with electrical conductivity. These coatings are usually thinner than Class 1A, and they have a lighter coating weight. Alodine conductivity is technically an incorrect term as the coating itself is not conductive; rather, the Class 3 coating is thin enough to permit the aluminum to retain its conductivity.

The following chart summarizes the key differences between the Types and Classes of chromate conversion coatings according to the MIL-DTL-5541 standard. This standard is also sometimes referred to as MIL-C-5541.

MIL-DTL-5541 Types and Classes for Chromate Conversion Coating

| MIL-DTL-5541 Standard | Type 1 | Type 2 |

| Chromates | Hexavalent Chromate | Hex-Free Chromate (Trivalent Chromate) |

| Class 1A | Maximum corrosion protection | Maximum corrosion protection |

| Class 3 | Improved electrical conductivity with corrosion protection | Improved electrical conductivity with corrosion protection |

Alodine Chemical Conversion Coating Tank

Alodine Process for Aluminum Treatment

The chemical film / Alodine process steps vary for Type 1 vs. Type 2. The Type 2 chemical conversion coating process allows for use of either an alkaline or acid cleaner. Though the time varies according to the part and process type, it typically takes each part ten minutes to a half-hour to go through the process of chromate coating on aluminum.

Type 1 Chromating Process

The Type 1 hexavalent chromate conversion coating process (Alodine process) includes 9 process steps.

- Clean: A general washing in a cleaning solution takes place as a pre-process step. This ensures that dirt, oil, and any residue formed from prior manufacturing or packaging processes is removed before the chromate coating begins. Then a rinse and dry takes place.

- Rinse: Ensure any alkaline detergents are removed from the part. A water-break-free test is often performed.

- Etch: If there are any areas that the chem film coating should not be applied to, the etching process covers those areas.

- Rinse: Ensure any etching chemistry is rinsed to stop the etching process.

- Deox: Deoxidation of the part occurs next, to remove any excess materials and oxides, contaminants and chemicals.

- Rinse: Remove any deox solution.

- Chem film coat: The surface conversion process takes place when the aluminum is immersed in the tank. The chromate conversion coating gets applied immediately. The period of time that it remains in immersion varies based on the method of the application, the composition of the chemical film and the composition and size of the part itself.

- Rinse.

- Warm rinse.

Video: Chem Film/Chromate Conversion Alodine and Passivation 14-Tank Line

Type 2 Chromating Process

The Type 2 hex-free chem film process for surface conversion (chromate conversion) with TCP-HF has two variations, Acid Clean and Alkaline Clean.

Acid Clean Chem Film process

- Acid Clean

- Rinse

- Trivalent chromium, hex-free chrome coat

- Rinse

- Second Rinse is used in the Type 2 method of surface conversion coating known as TCP-HF.

The alternative Type 2 hex-free chem film process for conversion is known as Alkaline Clean process.

Alkaline Clean Chem Film process

- Alkaline Clean

- Rinse

- Deox

- Rinse

- Trivalent chromium, hex-free chrome coat

- Rinse

- Second Rinse is used in the Type 2 method of surface conversion coating known as TCP-HF.

It’s important to deoxidize the part prior to trivalent chrome processing. While deoxidizing is inherent in the Type 2 Acid Clean Chem Film process, the Type 2 Alkaline Clean process requires 2 additional steps to deoxidize and rinse the part prior to trivalent chrome processing.

Best Technology can build equipment for Type 1 or Type 2 chromate conversion coatings.

Type 2 Chem Film / Chromate Conversion Coating Tank System

Testing per MIL-DTL-5541 Specification

The U.S. Department of Defense was the first to use TCP-HF (trivalent chromium, hex-free) and this trivalent chromate conversion coating has become such an accepted standard that a detailed specification, MIL-DTL-5541, included it. Test cycles according to this standard usually run 168 hours in a salt-fog chamber, using a five-percent salt spray. Tests are usually performed by companies on a monthly basis, with test panels, because the test is a destructive procedure.

Anyone wishing to do work with the U.S. government and military will need its product to undergo two years of Naval testing and validation, and, meeting or exceeding requirements, will become QPL (Quality Parts List) certified. Another certification to look for is Nadcap (National Aerospace and Defense Contractors Accreditation Program), which has very stringent requirements to get certified.

The TCP-HF (hexavalent free) conversion coating chemistry offered by Best Technology is both QPL-listed and Nadcap-certified.

Whether your needs are Type 1 or Type 2 (TCP-HF), call on Best Technology for all of your chemical conversion coating equipment needs!

Standards and Specifications for Conversion Coatings

| Standard | Title / Description |

| MIL-DTL-5541 |

Military Specification, Chemical Conversion Coatings on Aluminum and Aluminum Alloys

|

| MIL-DTL-81706 |

Military Specification, Chemical Conversion Materials for Coating Aluminum and Aluminum Alloys

|

| ASTM B449 |

Standard Specification for Chromates on Aluminum

|

| ASTM B921 |

Standard Specification for Non-hexavalent Chromium Conversion Coatings on Aluminum and Aluminum Alloys

|

| AMS 2473 |

Chemical Film Treatment for Aluminum Alloys, General Purpose Coating

|

| AMS 2474 |

Chemical Treatment for Aluminum Alloys, Low Electrical Resistance Coating

|

| ISO 8081 |

Aerospace process, Chemical conversion coating for aluminum alloys, General purpose

|

| BAC 5719 |

Chemical Conversion Coatings for Aluminum and Aluminum Alloys

|

Chromate Coating Equipment for Aerospace

Common Applications for Chem Film Coatings

What is a conversion coating used for? Chem film coatings on aluminum are used in a variety of industries.

- Aerospace: Aircraft travel at very high rates of speed. The high speed coupled with atmospheric gases at extremely high altitudes contributes to corrosion of aircraft parts. As a result maximum protection is necessary for as many parts as possible. Even passing through clouds can cause corrosion of aircraft parts. Aluminum corrosion protection is critical to aerospace metal finishing applications and an Alodined or aluminum chromate coated aerospace part can prevent surface exposure to such elements.

- Maritime/Naval: Watercraft, large and small, need to be as resistant to corrosion as possible. Boat interiors and mechanical parts can be impacted by water damage, especially boats meant to be in saltwater. Conversion coating allows parts to withstand corrosive saltwater environments and pass salt-spray testing methods. The anti-corrosive properties of chemical films are in high demand for this purpose. The chromate coating’s qualities as a paint primer can be useful here too, for custom colors on watercraft.

- Military and defense: The U.S. Department of Defense uses chemical film in a variety of ways. Such a large number of military parts are primed and protected with Alodine chem film coating, that the U.S. military has created a standard for the finishing method, with detailed specifications. The standard MIL-DTL-5541 regulates the chem film chemical coating treatment and places chemical conversion coatings into categories based on their applications. Brushed-on chem film is also used to repair surfaces and components that have been anodized.

- Electrical industry: Electricians appreciate the corrosion protection when they apply a surface conversion coating to wire housing, which holds and/or protects wiring. This helps to prolong the life and performance of the wires. Alodine coatings in the electrical industry provide not only corrosion protection to wire housings and panels but also reduction of electrical conductivity losses.

Chem Film Equipment for Alodine-Treated Aluminum

Chem Film Coating Best Practices

The quality of the material, and the material type, go a long way to determine the outcome of the surface conversion. Variations in the purity or overall quality of the material, will affect the final appearance after the Alodine process steps. The class of the chemical film will also have an effect on the chromate finish: Class 1A chem film is thicker and darker than the lighter, thinner Class 3 chem film.

The preparation stages of chromate conversion coatings are important too. Ineffective rinses can lead to contaminated tanks. Improper acid activation or pH levels in tanks can reduce quality of the results. Allow the experts at Best Technology to handle the details and build a chem film line for you, so that parts get cleaned and your chromate conversion coating process meets the highest standards.

Chem Film / Alodine / Chromate Conversion FAQs

-

What is aluminum chromate conversion coating?

A chromate conversion coating is a type of chemical conversion coating that is typically applied to aluminum alloys. Other types of chemical conversion coatings include iron phosphate and zinc phosphate coatings, typically applied to steel.

A chromate conversion coating protects the underlying aluminum against corrosion, serves as a base for paint adhesion, and can allow for electrical conductivity when applied as a thin coat.

Chromate coating on aluminum is widely used in the aerospace industry, as well as with everyday hardware such as nuts and bolts.

-

What is chem film?

Chem film, also called chemical film, is a chemical conversion coating. It typically refers to a chromate conversion coating applied to aluminum and its alloys. The chemfilm coating provides a layer of corrosion protection and a base for paint and primer. When applied as a thin coat, chem film can allow for electrical conductivity.

Chem film coatings are marketed under brand names such as Alodine®, Iridite® and Chromicoat®.

The chemfilm coating process is often governed by the commonly used MIL-DTL-5541 standard, which specifies different types and classes of chem film coatings.

-

Is Alodine conductive?

What is the electrical conductivity of chromate conversion coatings, also called Alodine® or chem film, when applied to aluminum alloys?

Unlike anodizing, Alodine coatings offer electrical conductivity for aluminum parts, when applied according to Class 3 of the MIL-DTL-5541 standard. Class 3 chemical conversion coatings protect against corrosion where low electrical resistance is required.

Coating Thickness

Because Class 3 coatings are thinner, they provide less corrosion resistance than Class 1A, but the trade-off is better electrical conductivity.

Technically the coating itself is not conductive, but rather the Class 3 coating is thin enough to allow the aluminum to retain its electrical conductivity.

Surface Roughness

The other factor that affects Alodine conductivity is surface roughness. A rougher surface finish allows greater conductivity due to breaks in the coating. In contrast, highly polished surfaces have lower conductivity due to lack of breaks in the coating.

To meet the Class 3 MIL-DTL-5541 standard, parts must have electrical resistance of no more than 0.005 – 0.010 ohms per square inch under nominal electrode pressure of 200 psi with a flat contact.

Applications

Common applications for electrically conductive Alodine coatings include parts that need to be electrically grounded.

In addition to electrical conductivity, Alodine coatings offer thermal conductivity and are used in applications such as heat sinks.

Chromate conversion coatings such as Alodine are an effective solution for aluminum alloys when both corrosion resistance and conductivity are important.

-

Alodine vs. Anodize: What’s the difference?

Wondering about the difference between chem film vs anodize?

The primary difference between Alodine (chem film) and anodizing is that anodizing is an electrolytic process and Alodine (chem film) is not.

Alodine (chem film) and anodizing are both processes used in aluminum finishing to improve corrosion resistance. Both transform the outer layer of the surface of the metal.

But Alodine (chem film) and anodizing are NOT the same.

Anodizing is an electrolytic finishing process that applies electrical current to the metal while it is immersed in an electrolyte solution. In addition to increased corrosion resistance, aluminum anodizing is used for improved lubrication or to allow dyeing (coloring). It is generally more expensive to anodize than to apply chem film and requires greater technical expertise.

In contrast, Alodine (chem film) coatings do NOT apply electrical current to the aluminum. The metal is immersed in a tank, often at room temperature. Compared to anodizing, chem film is less expensive and requires less technical expertise. Unlike anodizing, a chem film coating can allow aluminum to retain electrical or thermal conductivity. This makes chem film the preferred choice when aluminum parts need to be electrically grounded.

Best Technology offers equipment for Alodine (chem film) and titanium anodizing, but we do not currently offer equipment for aluminum anodizing.

-

What is chemical conversion coating?

What is a chemical conversion coating and how is it used?

A chemical conversion coating is a surface treatment applied to metals in which the metal undergoes a chemical reaction at the surface. This chemical reaction transforms the metal surface into a thin protective layer.

When applied to aluminum, a chemical conversion coating is sometimes called an aluminum conversion coating.

Chemical conversion coatings provide increased corrosion resistance and a uniform, inert surface for powder coating or paint adhesion.

Chemical conversion coatings are typically applied via immersion in a chemical tank or bath, or by brushing or spraying.

Types of chemical conversion coatings vary according to the metal substrate:

- Iron phosphate coatings – Used with steel

- Zinc phosphate coatings – Used with galvanized steel

- Chromate conversion coatings – Used with aluminum alloys

Best Technology offers phosphating tank lines for iron phosphate coatings and zinc phosphate coatings, and Alodine tank lines for chromate conversion coatings. Our chemical department offers trivalent chromate conversion coating chemistry for use on aluminum alloys.

Other Materials Protected from Corrosion by Chem Film

While aluminum is what is typically used for chemfilm, other metal alloys such as copper, magnesium, cadmium and tin also benefit from the protection against corrosion that chromate conversion coating offers.

Steel and iron are not compatible with chem film when applied directly. But zinc-plated steel can be treated with chemfilm to achieve added durability and protection against white corrosion. On iron substrates, a chromate conversion coating can be added to improve the durability of a phosphate conversion coating.

Aluminum Corrosion Treatment Products

| Product | Manufacturer | Sample Products | Chemistry |

| Alodine | Henkel | Alodine 1200S, Alodine 1201, Alocrom 1200 (U.K.), Alodine 1132 pen, Alodine 600 |

Chromate conversion coating for aluminum, contains hexavalent chromium. Resulting color is iridescent gold or yellow to tan. Also known as yellow chromate. |

| Alodine 1000 clear, Alodine 1001 clear, Alodine 1500 clear |

Chromate conversion coating for aluminum, contains hexavalent chromium. Resulting color is clear. Also known as clear chromate or clear chem film. | ||

| Alodine 871 | Non-hexavalent (hex-free) chromium conversion coating for aluminum | ||

| Alodine 5200, Alodine 5700 |

No-Chromium (hexavalent or trivalent) alternative treatment for aluminum or magnesium. | ||

| Iridite | Macdermid | Iridite 14-2 | Chromate conversion film for aluminum and its alloys |

| Iridite 15 | Chromate conversion treatment for magnesium and its alloys | ||

| Iridite NCP | No-Chromium (hexavalent or trivalent) alternative to chromate-based treatments for aluminum | ||

| Bonderite | Henkel | Bonderite 1020, Bonderite 1030 |

Iron phosphate conversion coatings for application to steel surfaces |

| Bonderite 3410 | Zinc phosphate conversion coating for application to steel, zinc and aluminum | ||

| Bonderite NT-1 | Zirconium-based, non-phosphate alternative to traditional iron phosphate, for application to steel, zinc, and aluminum | ||

| Chromicoat | Chemetall | Chromicoat L25 | Chromate conversion coating for aluminum, contains hexavalent chromium |

| TCP-HF (Hexavalent free) | Chemeon | TCP-HF, eTCP |

Trivalent chromium (hex-free) conversion coating for application to aluminum, magnesium, zinc, zirconium and other alloys |

Video: Chem Film Chromate Conversion Type 1 System

Bring your aluminum chromating process in-house. Get a chromate conversion coating system from Best Technology. Contact us today for a free quote!