Electropolishing machines produce a bright, highly-polished, smooth finish on metal objects. Our electropolishing equipment offers the assurance of repeatable, micro-tolerance surface finishing for stainless steel, cobalt chrome and other materials. The high-quality, consistent results aid in process validation for regulatory and industry requirements.

Wet Bench Electropolishing Machines

Electropolishing wet benches offer the convenience and efficiency of an all-in-one, multi-tank system that combines washing, rinsing, electropolishing, and drying into a single, unified piece of equipment.

An electropolishing wet bench, also known as an electropolishing console, stands on the floor, in contrast to benchtop electropolishers that sit on a bench or table. With a wet bench, the bench is integrated into the equipment design. Lockable casters on the wet bench make it possible to wheel the entire system to another room if necessary, and then to lock the system in place so it doesn’t move around during use.

Wet benches also provide the convenience of plumbing and electrical connections in one easy location, rather than wiring and plumbing each tank individually.

Electropolishing wet benches are intended for use in production, not just occasional laboratory use or for prototyping. Our electropolishing machines are built with sturdy materials to withstand the rigors of daily use in full-scale production.

Construction Materials for Electropolishing Machines

Typical construction materials are polypropylene for the electropolishing tank and stainless steel for the bench, but other configurations are available. Alternate construction materials for the electropolishing tank include PVDF (also known as Kynar®) and CPVC (also known as Chlorinated PVC or PVC-C), depending on the chemical-handling requirements for the electrolyte.

Our application engineers bring decades of experience to the design of each electropolishing system. Best Technology’s electropolishing wet benches are custom designed according to each client’s specific application, providing maximum flexibility. Custom specifications include:

- Size of rectifier and amperage range

- Tank volume and dimensions

- Number and placement of cathodes.

Contact an electropolishing expert today to start designing your electropolishing wet bench.

Electropolishing Wet Bench with Ultrasonic Cleaning

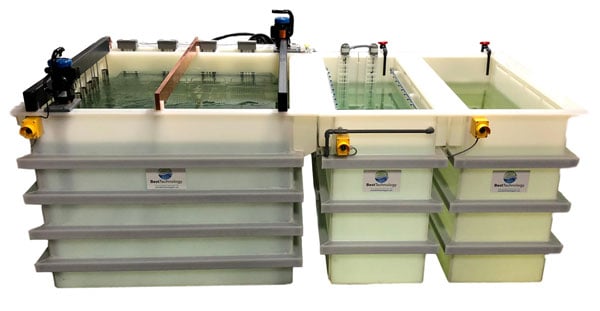

This all-in-one electropolishing wet bench incorporates 6 stations into a single console, to perform the following functions:

- Ultrasonic Washing

- Ultrasonic Rinsing

- Electropolishing

- Dead Rinsing / Static Dip

- Ultrasonic Rinsing

- Heated-Air Drying.

Tank capacity for each tank is 6 gallons, except for the electropolishing tank, which has a capacity of 11 gallons, to accommodate heat displacement of the electrolyte solution. Each ultrasonic tank has a watt density of 100 watts per gallon, or 600 watts per tank. Each rinse tank uses an overflow rinse to drain debris from the surface through an overflow standpipe.

Constant-Current Rectifier for Precision Polishing

With 200 amps of high-precision electropolishing power, the specialized rectifier on this unit provides true constant current or constant voltage to ensure precise, repeatable material removal for each workpiece. The rectifier can control the current from 0-200 amps, or it can control the voltage from 0-30 volts of DC power. The digital timer can control the electropolisher to a precision of 0.1 second.

The electropolishing tank includes a heater that can generate 1000 watts to heat the electrolyte solution to the desired range of 170 °F – 180 °F, and a digital temperature controller. For safety the heater has a high-temperature shutoff switch that turns off the unit in the event of overheating.

Electropolishing machines use inert materials for cathodes and anode (workpiece) holders. This machine features a titanium cathode and titanium clips for workpiece holding.

Lip Ventilation for Worker Safety

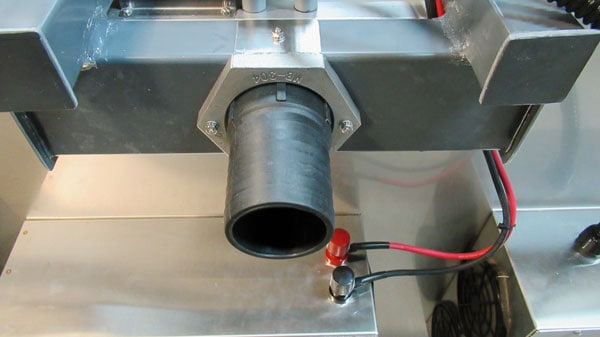

Many electrolyte chemistries use phosphoric acid and sulfuric acid and can pose a fume hazard for electropolishing equipment and operators. One method to contain electrolyte fumes is to use lip ventilation on the electropolishing tank.

Lip ventilation provides an air channel along the edges at the top of the electropolish process tank. The air channels connect to an exhaust vent at the back of the tank. By connecting this vent to customer-supplied blowers and ventilation, the fumes can be processed through facility exhaust, allowing the machine operator to safely electropolish parts in an open tank.

Example process steps for electropolishing equipment in a wet bench:

- Ultrasonic alkaline cleaning – Remove any oils, grease, fingerprints, etc.

- Ultrasonic rinse – Remove alkaline solution

- Electropolish – Apply electrochemical polish process

- Drag-out (Dip) – Remove drag-out electrolyte via overflow rinse; also known as dead rinse or static dip

- Ultrasonic rinse – Remove additional electrolyte

- Hot-air drying – Remove byproducts of sulfates, phosphates and chromates of heavy metals, which are difficult to remove by water rinsing alone.

Note that some electropolishing systems require the use of a dip tank or dead rinse, as in step 4 above. The dead rinse captures most of the used electrolyte solution. Because of the dissolved metal in the electrolyte, it must be disposed of safely by a service like Safety-Kleen, and not simply flushed down a drain.

For more information on ultrasonic cleaning and ultrasonic rinsing, please see our pages on How Ultrasonic Cleaners Work.

Need Larger Electropolishing Tanks?

Electropolishing machines on this page feature multiple tanks integrated into a single unit known as a wet bench or console. Some large-scale applications require a separate piece of equipment for each process step, with each tank a separate floor-standing unit and the series of tanks forming an electropolishing line.

For more information on electropolishing lines, please see our Large Scale Electropolishing page.

For more information on electropolishing lines, please see our Large Scale Electropolishing page.

Electropolishing Equipment & Process FAQs

-

What is electropolishing?

Electropolishing is an electrochemical process that removes material from a metallic part, typically stainless steel or similar alloys. The part is immersed in a temperature controlled bath of electrolyte (typically mixtures of sulfuric acid and phosphoric acid). The part serves as the anode as it is connected to the positive terminal of a DC power rectifier. The negative terminal of the rectifier is attached to the cathode which is typically made from titanium or other alloys which do not dissolve during the electropolishing process.

Visit What is electropolishing? How does electropolishing work? for more detailed information on electropolishing.

-

What’s the difference in passivation and electropolishing?

As a non-electrolytic process, passivation uses solutions like citric and nitric acids instead of an electrical current used in electropolishing to create a inert oxide layer / film and remove free iron and foreign matter from metal surfaces.

Electropolishing, a non-mechanical interactive process, can be used on objects with complex geometries. The electropolishing process uses a combination of electrolytic chemicals and an electrical current to carefully eliminate imperfections and contaminants of metal part surfaces. This particular process is an alternative to abrasive fine polishing.

Electropolishing can be used to polish, deburr, and smooth metal components whereby doing so also causes material removal to occur including the free irons on the surface of the part. Electropolishing would be the more appropriate approach when aesthetics are necessary. A smoother, polished surface can result from electropolishing.

Passivation, on the other hand, does not change or brighten the surface appearance, and is not an effective method for improving surfaces that have been welded with oxide heat effect scale or heat treated.

-

How many amps of current will it take to electropolish a part?

The current or amps required to electropolish a part is primarily based on the surface area of the part or total surface area if multiple parts are desired to be electropolished at the same time. More information on electropolishing can be found on What is electropolishing? How does electropolishing work? page

Visit the Electropolishing Current Required Calculation Spreadsheet to calculate the approximate current amperage required for electropolishing

-

How long will it take to electropolish a part?

The cycle time required to electropolish a part is primarily based on the current / amps and surface area of the part or total surface area and rectifer current if multiple parts are desired to be electropolished at the same time.

Visit the Electropolishing Current Required Calculation Spreadsheet to calculate the approximate cycle time required for a part or total parts for electropolishing.

What is electropolishing? How does electropolishing work? contains more in depth information on electropolishing.

Common Applications for Electropolishing Wet Benches

- Medical device stent polishing and deburring of stainless steel and cobalt chrome

- Industrial stainless steel 300 series polishing to reduce surface roughness and burr removal

- Reducing friction and ensuring top performance on flight-critical aerospace parts

- Reducing friction, boosting performance and extending life on automotive and racing industry parts

Common Configurations

Electropolishing wet benches offer great flexibility in sizing. Although each unit is custom-built to the requirements of your application, below are a few common configurations for electropolishing wet benches. Other sizes can be customized to fit your application.

| Liquid Capacity per Tank (gallon) |

Inside Working Zones (l x w x h) |

| 3.5 | 12″ x 10″ x 8″ |

| 5 | 14″ x 9.5″ x 9″ |

| 9 | 18″ x 10″ x 12″ |

| 18 | 20″ x 12″ x 18″ |

Rectifiers for electropolishing wet bench consoles typically run from 25 to 200 amps. Other ranges are available, and our large-scale electropolishing systems typically run from a few hundred amps to several thousand as dictated by the application. To estimate rectifier size requirements in amps for electropolishing stainless steel, visit our Electropolishing Cycle and Current Calculator.

Learn from an electropolishing expert

At Best Technology, our application engineers have over 30 years’ experience in designing electropolishing systems for our customers. You can count on our experience for repeatable surface polishing and material removal for medical device and aerospace metal parts. Contact an electropolishing expert today to discuss your project and receive a free proposal.