What is Hexavalent Chromium?

Often referred to as hex chrome, hexavalent chromium is a form of the metallic element chromium, commonly used in manufacturing. Chromium is especially useful for its corrosion resistance, hardness and durability. Other names for hex chrome include chromium(VI), chrome VI, chromium 6, chromium(6+) and Cr VI. Hexavalent chromium compounds contain the element chromium in the +6 oxidation state.

Chromium occurs naturally in the environment in three oxidation states:

- Trivalent chromium compounds (Cr III) – Most common.

- Hexavalent chromium compounds (Cr VI) – Less common; most hex chrome is produced through industrial processes.

- Metallic chromium (Cr 0) – Least common.

Hexavalent chromium is toxic and a known carcinogen, and its use is highly regulated. In contrast, trivalent chromium is non-toxic, and is considered an essential dietary mineral in low doses for normal metabolism. Metallic chromium is also non-toxic.

How is Hex Chrome Used?

-oxid.jpg) The most common use of chromium is in the formation of stainless steel. When metallic chromium is added to steel, the resulting stainless steel is significantly more resistant to corrosion.

The most common use of chromium is in the formation of stainless steel. When metallic chromium is added to steel, the resulting stainless steel is significantly more resistant to corrosion.

Though the metallic chrome in stainless steel is non-toxic, it may transform into hex chrome during “hot work” such as welding. The high temperature can lead to oxidation and convert the chrome to the hazardous hexavalent chrome.

Another primary use of chromium is in chrome plating. Metal parts can achieve a shiny polished look that resists corrosion through electroplating with chromic acid. Shiny metallic bumpers on older cars are an example of chrome plating.

For aluminum parts, the chromium in a chromate conversion coating (also called chem film) adds significant corrosion resistance and other benefits.

Other uses of chromium include chromate pigments in paints, textile dyes and printing inks, as well as leather tanning and wood preservatives.

Health Effects of Hexavalent Chromium

According to the U.S. National Institute for Occupational Safety and Health (NIOSH), hexavalent chrome is “a well-established occupational carcinogen associated with lung cancer and nasal and sinus cancer.” The most common form of hex chrome exposure is through inhalation of dust, mists or fumes. Symptoms of exposure to airborne hex chrome include sinus irritation, nosebleeds, shortness of breath, wheezing, and perforation of the tissue between nostrils of the nose.

Adverse effects to hex chrome due to dermal exposure can also occur. Symptoms include skin ulcers and irritation, and allergic contact dermatitis.

In popular culture, hexavalent chromium was the chemical at issue in the 2000 movie Erin Brockovich.

Hexavalent chromium appears on the International Agency for Research on Cancer (IARC) Group 1 list of known carcinogens. In Europe, hex chrome is listed as a substance of very high concern (SVHC) under REACH regulations. The phase-out of hex chrome plating in the European Union is in progress, with a ban expected in 2024. In California, the California Air Resources Board is seeking an outright ban on hex chrome in decorative plating and anticorrosive coatings.

Hex Chrome Exposure Limits

The trend in hex chrome exposure limits is toward lower exposure limits.

The U.S. Occupational Safety & Health Administration (OSHA) has set the Permissible Exposure Limit (PEL) for hexavalent chrome at 5 micrograms per cubic meter of air over 8 hours. Another metric, the Action Level (AL), requires employers to take certain actions if the hex chrome level is at or above 2.5 micrograms per cubic meter of air in an 8-hour time-weighted average (TWA).

The U.S. National Institute for Occupational Safety and Health (NIOSH) has set the Recommended Exposure Limit (REL) for hex chrome at an even more stringent level. The NIOSH REL for hexavalent chrome is 0.2 micrograms per cubic meter of air in an 8-hour TWA.

Similarly, in 2018 the American Conference of Governmental Industrial Hygienists (ACGIH) significantly reduced the Threshold Limit Values (TLV) for exposure to hex chrome. The TLV-TWA for hexavalent chrome aligns with NIOSH at 0.2 micrograms per cubic meter of air.

Hexavalent vs. Trivalent Chromium: What’s the difference?

Chemically, the difference between hexavalent and trivalent chromium compounds is the oxidation state. Hex chrome compounds contain chromium in the +6 oxidation state, while trivalent chrome compounds contain chromium in the +3 oxidation state.

Hex chrome compounds are more toxic because they can more easily enter living cells than trivalent chrome compounds.

Hexavalent chromium has a longer history of use in manufacturing. But in recent years, use of trivalent chromium has grown with its reputation as the safer and more environmentally friendly alternative to hexavalent chrome.

Hexavalent vs. Trivalent Chromium Exposure Limits

| Exposure Limits | Hexavalent Chromium compounds |

Trivalent Chromium compounds |

| Regulatory Limits | ||

| OSHA PEL – 8-hour TWA (mg/m3) | 0.005 | 0.5 |

| Recommended Limits | ||

| NIOSH REL – 8-hour TWA (mg/m3) | 0.0002 | 0.5 |

| ACGIH TLV-TWA (mg/m3) | 0.0002 | 0.003 |

Chromium Trioxide vs. Trivalent Chromium: What’s the difference?

Chromium trioxide and trivalent chromium may sound alike, but they’re not the same.

Chromium trioxide (CrO3) is one type of hexavalent chromium compound. Not all hex chrome is chromium trioxide, but all chromium trioxide is hexavalent chrome. Chromium trioxide is also written as chromium(VI) oxide. Chemically, chromium trioxide is a single chromium in the +6 oxidation state bound to three oxygen atoms. Like other hexavalent chromium compounds, chromium trioxide is toxic and carcinogenic.

Trivalent chromium (Chromium III) refers to chromium compounds that contain the element chromium in the +3 oxidation state. Trivalent chromium compounds have low toxicity. Chromium(III) oxide (Cr2O3) is an example of a trivalent chromium compound.

Alternatives to Hex Chrome for Chromate Conversion Coating

Many aerospace and military applications require coating of aluminum parts with a conversion coating for durability and corrosion protection. The military specification for these conversion coatings, MIL-DTL-5541, allows for use of hexavalent (Type 1) or trivalent (Type 2) chrome coatings.

Best Technology is proud to offer Chemeon’s TCP-HF line of trivalent chrome conversion coating products. TCP-HF provides a safer, more environmentally friendly alternative to hexavalent chromate conversion products like Alodine.

TCP-HF Replaces Hex Chrome Conversion Coatings

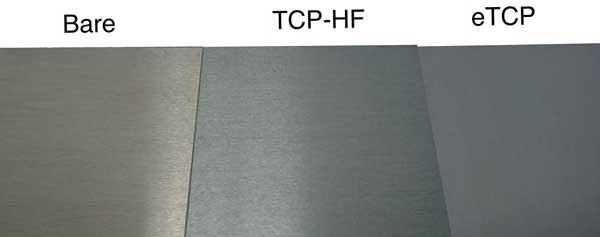

TCP-HF is a trivalent chromium conversion coating designed as a drop-in alternative to hex chrome coatings for aluminum. The initials in TCP-HF stand for Trivalent Chromium Pretreatment – Hex-Free.

A related product, eTCP (Enhanced Trivalent Chromium Pretreatment), offers the advantages of TCP-HF, with the addition of dye that allows quality inspectors to distinguish easily between treated and non-treated surfaces. Surfaces treated with eTCP have a purplish color that is distinct from untreated surfaces.

Advantages of Trivalent Chromium for Conversion Coating

In addition to improved worker safety, trivalent chrome coatings offer the advantage of fewer process steps, and lower processing temperatures that reduce evaporative losses. Both TCP-HF and eTCP perform as well as or better than hexavalent chrome coatings in salt-spray tests against corrosion.

Hex Chrome vs. Trivalent Chromium Coating Comparison

| Hexavalent Chromium Coating (e.g., Alodine 1200 / Bonderite M-CR) |

Trivalent Chromium Coating (e.g., TCP-HF or eTCP) |

|

| Hex Chrome status | Contains hex chrome | Does not contain hex chrome |

| Safety profile | IARC Group 1, known to cause cancer in humans | IARC Group 3, not known to cause cancer in humans |

| Regulatory | Subject to strict regulations by OSHA and EPA. Phase-out in progress in the U.S. and Europe. | Not restricted in U.S. Complies with EU REACH guidelines. |

| Ventilation | Requires additional ventilation for worker protection | Little or no additional ventilation required |

| OSHA Exposure Limit (8-hour TWA) | 0.005 mg/m3 | 0.5 mg/m3 – 100 times more than hex chrome |

| Color | Yellow, gold, clear | Blue, purple, clear |

| Corrosion Prevention | Meets MIL-DTL-5541 standards | Exceeds MIL-DTL-5541 standards |

| Cost |

|

|

| Process Temperature (immersion) |

68 to 95 °F (20 to 35 °C) |

68 to 80 °F recommended (20 to 27 °C) |

| Process Duration (immersion) |

15 seconds to 3 minutes | 5-6 minutes recommended |

| Operating pH | 1.3 to 1.8 | 3.8 to 3.9 recommended |

| Shelf Life | 48 months in unopened original packaging | 12 to 24 months from date of manufacture |

| MIL-DTL-5541 | Meets Type 1 requirements | Meets Type 2 requirements |

| QPL-81706 | Meets Type 1 requirements | Meets Type 2 requirements |

Conversion Coating Equipment

Check out our Chem Film Tank Line page for chem film equipment compatible with either hex-free or hex chrome conversion coating operations.

Trivalent Conversion Coating Price and Ordering

Please contact our chemical sales department for a quote on conversion coating chemistry by clicking the “Get a Quote” button, or call 612-392-2414, ext. 2