For one medical device manufacturer, the design of a citric passivation solution faced two major challenges:

- The manufacturing process required performing a water-break test after cleaning parts, before proceeding to passivation. This meant that they could not use a fully automated passivation solution.

- The system had to have data tracking for quality control purposes.

Semi-Automated Inline Citric Passivation Solution Video

Enter the Best Technology Semi-Automated Inline Citric Passivation Solution.

Data Tracking, Solved

Data tracking empowers quality control managers to quickly recognize causes of failures, and to provide proactive feedback to prevent potential failures. Data tracking is also known as indexing.

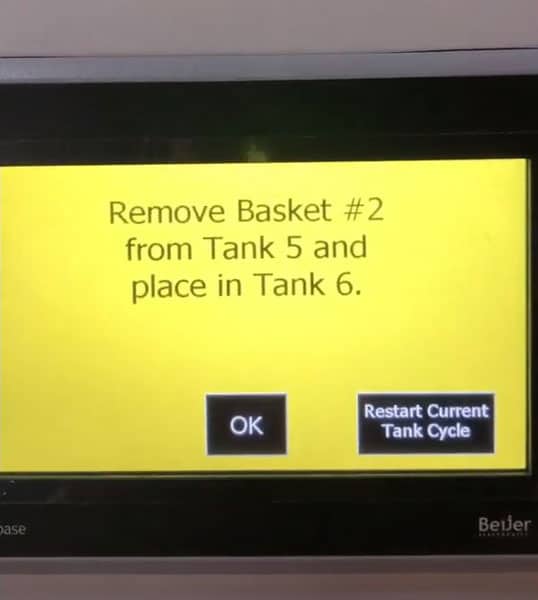

The Best Technology Semi-Automated Inline Citric Passivation system has a fully programmable interface that allows parts to be indexed. When an operator starts a job, they enter the job number, employee ID and basket number into the HMI (Human-Machine Interface). The system then logs the time each basket spends at each station, and the temperature at the beginning of each process step.

Semi-Automation, Solved

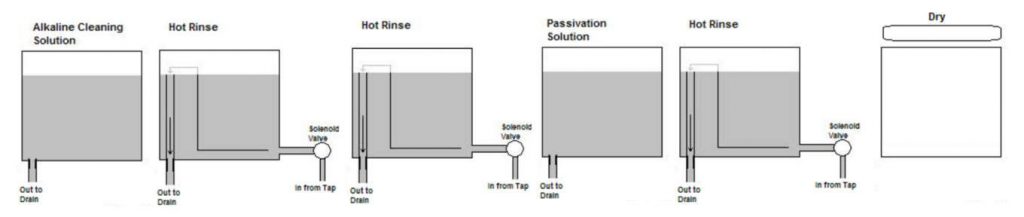

This passivation system features 5 ultrasonic wet tanks (wash, DI rinse, rinse, citric passivate, rinse) and a drying chamber. Manufacturing process specifications called for a water-break test to be performed on the parts after rinsing and before citric passivation.

This system allows the operator to remove the basket of parts, take it to another piece of equipment for testing, and return the parts to the passivation chamber after testing. The console signals the operator when each stage is completed, and which tank to move the parts to next. These cues appear both on the PLC screen and with blinking LED lights next to each tank.

18-gallon Semi-Automated Inline Citric Passivation Console – Model E782RC

Tank capacity for each tank in this system is 18 gallons. Though the customer for this particular system required 18-gallon tanks, the tank size is customizable to a wide range of tank sizes. In addition, the number of tanks on this type of system can be customized.

The passivation chamber is compatible with citric acid solutions such as CitriSurf®. To learn more about citric acid passivation, please see our page on citric acid passivation. Compatibility with nitric acid passivation is also available as an option with this type of system.

The ultrasonic generators on each tank have a watt density of 100 watts per gallon, for a total of 1800 watts per tank. The hot-air dryer uses a 150 CFM fan with 3000 watts of heat.

Needle valves on the rinse tanks act as flow regulators, allowing the rinse tanks to slowly overflow. This cascade overflow rinse feature ensures continuously clean rinse water.

The system is completely flexible in programming to allow for various applications. Processing occurs from left to right. The order and number of cleaning, passivation and rinsing steps is arbitrary, with drying as the last step of the job cycle.

Portable Passivation System

The stainless steel console is equipped with 6-inch casters, so it can easily be moved to another location as needed. This offers portability for the entire passivation system to move from one manufacturing cell to another. The casters can then be locked in place to prevent further movement.

Need a fully-automated passivation system?

Check out our automated passivation equipment that moves the fluids, and not the parts! The operator places the parts in the processing chamber, presses the cycle start button, and the liquid solutions move from filtered storage tanks in and out of the processing unit. Much like a dishwasher, the operator comes back to remove the cleaned, passivated, rinsed and dried parts.

Bring your passivation in-house

For companies looking to bring their passivation process in-house and avoid the hassle of outside passivation vendors and plating shops, the semi-automated citric passivation solution from Best Technology is a great choice. Contact a passivation expert today to learn how you can benefit from the convenience and flexibility of your own citric acid passivation system.

CitriSurf® is a registered trademark of Stellar Solutions, Inc. McHenry IL USA.